2024.10.17

Mitsubishi UBE Cement Corporation is taking new steps toward carbon neutrality together with Osaka Gas, Mitsui & Co., Ltd., and others

Mitsubishi UBE Cement Corporation is starting new engagement with environmental measures such as CCUS and CCS. Let’s look at the unique circumstances and future prospects for the cement industry.

Mitsubishi UBE Cement Corporation is taking new steps in its environmental measures. In

March of 2024, the company started a joint examination into carbon capture, utilization and

storage (CCUS) for CO2 emissions with Osaka Gas Co., Ltd. (hereinafter referred

to as “Osaka Gas”), aimed at carbon neutrality in the cement manufacturing process. Then in

April, this was followed by the announcement of a joint study with Mitsui & Co., Ltd. which

was launched to build a value chain related to carbon capture and storage (CCS) at a

CO2 storage site being developed jointly with Malaysian state-owned oil company

and others.

These efforts are based on Mitsubishi UBE Cement Corporation’s medium-term management

strategy announced in April 2023, Infinity with Will 2025 — MUCC Sustainable Plan 1st Step,

with the company aiming at a 40% reduction in CO2 emissions from 2013 levels by

2030, and to achieve group-wide carbon neutrality by 2050. With a focus on these

initiatives, its policy is to continue contributing to the achievement of carbon neutrality

through collaborating with other industries and local governments.

Ube cement plant

Strengthening new efforts for CCUS, CCS

Next, let’s take a look at the specific details, turning first to the CCUS initiative with

Osaka Gas. It involves the recovery of CO2 emitted from thermal energy and cement

raw materials in cement kilns (furnaces used to make cement) at Mitsubishi UBE Cement

Corporation’s Kyushu Plant (Miyako-gun, Fukuoka Prefecture), which has the largest cement

production capacity in Japan. Mitsubishi UBE Cement Corporation will jointly build a value

chain for e-methane production and evaluate the economics side of such operation. It will

involve CO2 separation and recovery, liquefaction/storage, marine transportation

of liquefied CO2, and underground storage of CO2 for the purpose of

injecting and storing it deep underground and reusing it as e-methane.

Next, let’s take a look at the CCS initiative with Mitsui & Co., Ltd. Jointly with the CCS

business of a Malaysian state-owned oil company and the CCS business of French integrated

energy company TotalEnergies, Mitsubishi UBE Cement Corporation is planning to develop CCS

offshore Malaysia and start a storage business by around 2030. The project will involve

processes ranging from the separation and recovery to the liquefaction and storage of

CO2 emitted by Ube Cement Plant (Ube-shi, Yamaguchi Prefecture). In addition, it

will be responsible for operations ranging from the marine transport of liquefied

CO2 to Malaysia to the underground storage of CO2 off the coast of the

country. Mitsubishi UBE Cement Corporation will also investigate and study the necessary

technical requirements and costs for the establishment of a series of value chains.

Alliances with other companies are critical to building value chains

Presently, as a result of repeated mergers in Japan’s cement industry, the three leading

companies, including Mitsubishi UBE Cement Corporation, account for about 80% of the market

share. Cement operations necessitate large limestone mines and plants as well as a great

deal of heavy equipment, so there are few opportunities for ventures with limited funds to

enter the market. Also, there are hardly any imports due to the issue of transportation

costs and the different quality standards in each country. Therefore, competition is almost

exclusively from domestic companies in the same industry, and this is a characteristic of

the industry. Kenichi Goto, , Assistant Manager, Carbon-neutral Technology Promotion Office,

Global Environment Preservation Project explains the current state of the industry as

follows.

“Ten years ago, the domestic demand for cement was at about 45 million tons annually, but

currently it’s less than 35 million tons. Demand may appear high in urban areas such as

Tokyo, but demand in rural areas is not growing as it did in the past, and we’re seeing

annual declines in overall domestic demand. Also, labor shortages are becoming more serious

at construction sites, and construction schedules are often pushed back. Work is not

progressing and the annual use of cement is declining.”

“And although demand is on a declining trend, the cement industry has higher CO2

emissions

than most other industries as it uses coal for thermal energy and limestone (which emits

CO2

when heated) as a raw material. As such, the cement industry needs to take more proactive

steps toward solving this issue.”

Mr. Goto continues: “CCS is not commonly at use in the cement industry, so there is almost

no precedent for it at cement plants. While the cement industry has determined to move in a

carbon neutral direction, specific measures have yet to be clarified. In that sense, this

initiative represented a great challenge for us.”

In seeking to achieve carbon neutrality, there’s a limit to the impact of a single company’s

CCS initiatives. It’s imperative that we form alliances with other companies and build a

series of CCS value chains. You could say that this joint effort is a part of that.

Taking on the challenge of technical innovation for the emission limitation, recovery, and recycling of CO2

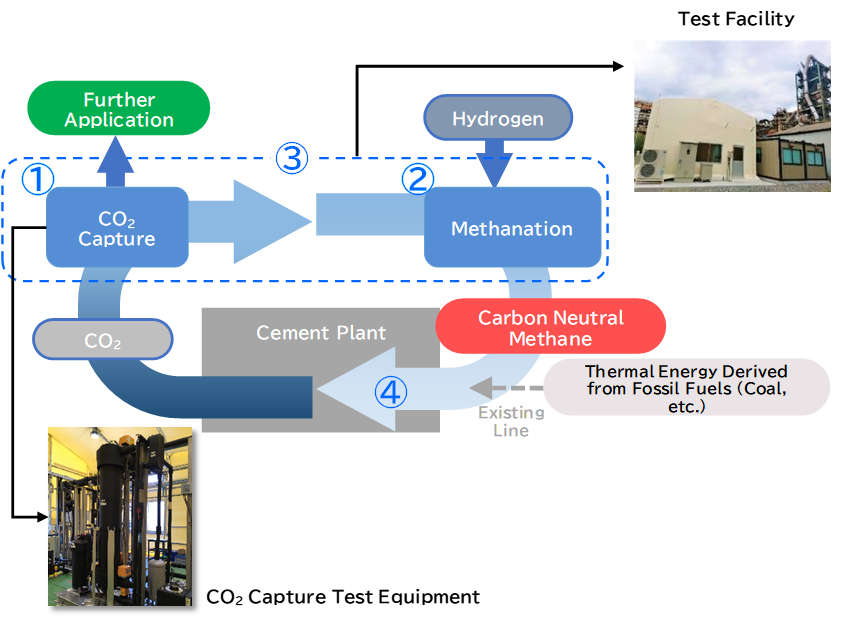

Regarding the Osaka Gas project, another new initiative is involved—methanation. It is a

form of technology for the recovery, hydrogen synthesis, and production of e-methane from

the CO2 emitted in the cement manufacturing process. This e-methane can be used

as a

substitute for raw materials in city gas and coal at cement plants. We asked Tomohiko

Takahashi, Assistant Manager, Cement Group, Cement Laboratory, Research & Development Center

at Mitsubishi UBE Cement Corporation about this kind of CCUS for the collection, storage,

and reuse of CO2.

“For this project, we installed the system in small-scale equipment at our Kyushu plant. Our

proof of concept for the methanation involved separating and recovering CO2 from

the gas

emitted by cement plants and using it for methane synthesis. It was a success, meaning we

have found a new way to reuse CO2.”

Figure1; Conceptual Diagram of Carbon Recycling

There is precedent for CO2 separation and recovery technology being installed at

chemical

plants and steel mills, but only on a small scale. CO2 recycling is also at use,

but not in

large-scale installations in cement plants yet in Japan.

Mr. Takahashi explains, “In reality, we at a stage where we do not know what the problems

will arise in CO2 recovery. Therefore, we are starting with small-scale

facilities,

repeatedly conducting studies to evaluate performance, identify problems, and take measures

to solve them. We have found a path to CO2 recovery and reuse through this

project, so now

we plan to expand the scale of our operations while building know-how.”

Mitsubishi UBE Cement Corporation is taking an active approach to achieving carbon

neutrality. We asked about Mr. Goto about the challenges the company will face in moving

forward with its policy.

“As you would imagine, we’re looking at cost increases. There’s a large investment required

that’s difficult to recover. We’ll continue closely monitoring the Japanese government’s

carbon pricing and other systems, and actively pursuing measures. However, I think it’s a

very difficult decision for the company to make at this point. We feel that the key point is

finding ways to reduce costs while enhancing the environmental value of our

products.”

The world is already on the path to carbon neutrality. The cement industry, which has high

CO2 emissions, will maintain its policy of initiatives in line with this

movement.

Mr. Goto says, “That is why we will continue our efforts to reduce and recover

CO2

emissions, while simultaneously actively taking on the challenge for technological

innovation, such as recycling. That will be our approach.”

INTERVIEWEES

Kenichi Goto

Assistant Manager, Carbon-neutral Technology Promotion Office, Global Environment Preservation Project

Tomohiko Takahashi

Assistant Manage, Cement Group, Cement Laboratory, Research & Development Center

Mitsubishi UBE Cement Corporation

2-1-1 Uchisaiwaicho, Chiyoda-ku, Tokyo, Japan

Mitsubishi Materials Corporation and UBE Corporation (formerly Ube Industries, Ltd.) integrated the two companies’ cement and related businesses, and Mitsubishi UBE Cement Corporation commenced operations in April 2022. Abbreviated as MUCC, the company’s number of consolidated employees stands at 8,070 (as of the end of March 2023). The company is involved in the cement and ready-mixed concrete businesses, the limestone resources business, environmental and energy-related business (coal business, electric power business, environmental and recycling business), and building materials business in Japan and overseas. It has approximately 110 affiliated companies.