2024.09.19

First in Japan! AGC Achieves Success in Demonstration Test of Solar Panel Cover Glass Recycling—A bright future for industrial waste reduction and reuse

A large quantity of solar panel cover glass is expected to reach the end of its useful life and be disposed of in the late 2030s, giving rise to concerns about a serious environmental impact. The success of this recycling trial opens possibilities for more extensive reuse.

In October of 2023, AGC was first in Japan to successfully conduct a demonstration test to

recover glass from used solar panel cover glass that has reached the end of its use. Then in

March of 2024, the same solar panel cover glass was used as raw materials for the production

of float glass—the first successful demonstration test of its kind in Japan. In addition to

reducing industrial waste, our new technology is expected to make possible the previously

technically difficult feat of recycling cover glass for float glass.

Photovoltaic power generation has become a focus among renewable energy sources. However,

the useful life of solar panels is estimated at 20 to 30 years, and several hundred thousand

tons are expected to be disposed of annually starting in the late 2030s. Cover glass

accounts for approximately 60% of the total weight of these panels, and the serious

environmental impact of landfilling and disposing it as industrial waste is raising

concerns. The company has succeeded in recycling cover glass into figured glass as of 2023,

but recycling it into the more versatile float glass has proven difficult.

However, this successful test has led to expectations that horizontal recycling of waste

cover glass into high production output float glass will be possible.

We spoke about the current initiatives with cover glass with Yoshihiro Nagao, Group Leader

of the Sustainable Management Initiatives Group, Architectural Glass Asia Pacific

Company.

“The amount of solar panel cover glass produced in Japan is very small and we are not

producing any at present. Most is imported from China. This is because China has a huge

production volume at low prices. However, if this continues, industrial waste will continue

to increase. This makes us feel that Japanese flat glass manufacturers should start talking

about the issue, so we discussed the matter within the company and decided to take on a new

recycling project.”

Recycled glass product

The majority of glass is not recycled?

Why does glass turn into industrial waste? This is not widely known, but the reality is

glass is not yet actively recycled. Glass would appear to be a material that could be

dissolved and reused many times. In truth, like plastic bottles, glass bottles are legally

recycled in accordance with the Containers and Packaging Recycling Law, but it is not

legally mandated that glass used in buildings and automobiles—including solar cover glass—be

recycled. Therefore, most glass is disposed of in landfills as industrial waste or

downcycled into roadbed material for asphalt roads.

The basic glass manufacturing process uses sand as the main raw material. It’s melted at

high temperatures in a furnace to produce transparent glass. Typically, in addition to sand,

glass cullet produced during the manufacturing process is also used as a raw material.

However, cover glass and glass dismantled from buildings often contains impurities that

adversely affect glass production, reducing productivity and possible causing defects. This

means using raw material cullet externally collected carries a high risk.

Glass is a delicate material, so it can’t be made into a product if it has a different

composition or contains impurities. Also, the difficulty of recycling varies between figured

glass and float glass. Mr. Naoya Kobayashi, manager of the same Group, provides the

following context.

“The type of glass product is determined by its application, and different types of glass

products are manufactured in different ways. Cover glass is often made using the figured

glass manufacturing method. Cover glass contains an impurity called antimony, which has a

negative impact on the float manufacturing process. Therefore, it’s difficult to recycle it

into float glass.”

However, the company has been researching suitable processing methods for flat glass

recycling for several years. With their recent success in recycling it as float glass, it is

now possible to expand recycling to a wider range of materials.

“Currently, we are looking beyond only solar cover glass, and are conducting research and

development to find ways to recycle glass from buildings and automobiles,” says Mr. Nagao.

Act now or the disposal problem will become unsolvable

What new issues will arise in the future of recycling of cover glass? We asked Mr. Nagao.

“It’s a question of economics. In general, people think that recycling will make glass

cheaper, but in fact, it becomes more expensive. Therefore, if recycling is more expensive,

customers will inevitably prefer to buy the new, cheaper products. But in the future, the

price of glass will start to rise as landfills for disposal fill up and disposal costs rise.

In that sense, right now we are merely postponing the problem. So rather than not do it

because it’s not economically viable, we are engaging in recycling with the idea in mind

that the problem won’t be solvable unless we start working on it now, for the sake of the

future.”

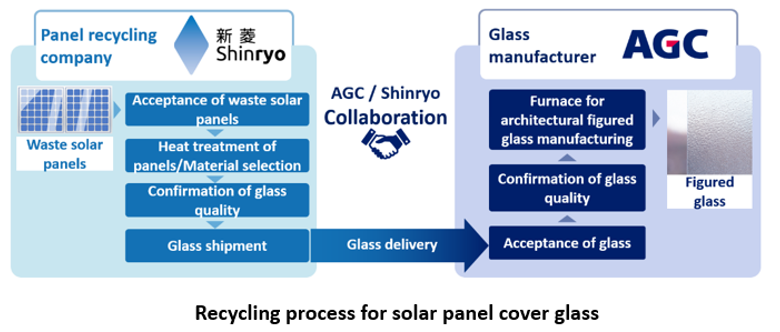

Another complication is establishing a supply chain to recover glass, which is also an issue

of economic feasibility. Further, the creation of partnerships with other companies is

another issue to be addressed. Currently, Shinryo Corporation, a member of the Mitsubishi

Chemical Group, is investigating the recovery of solar cover glass that has undergone heat

treatment.

Mr. Nagao on this topic: “In general, people don’t know that glass can be recycled, or that

it isn’t being recycled. At our company, we are hearing about advanced initiatives in

Europe, so we believe that we need to use this initiative to expand public awareness toward

glass recycling.”

In its medium-term management plan AGC plus-2026, the AGC Group defined three types of

social value that it wants to create through its products and technologies. One of these is

“Blue planet,” the Group aims at reducing the environmental impact of its products from raw

material procurement to use by customers toward the realization of a sustainable global

environment. The company will continue to provide value to society by accelerating the

effective use of resources.

We believe that recycling glass could generate a great deal of social value. It is in line

with trends like creating a circular economy. And since sand is a finite resource, promoting

recycling can protect the planet’s resources. And it would also be effective from the

standpoint of security. Going forward, we want to continue to promote recycling in

cooperation with many people,” says Mr. Kobayashi

The AGC Group has reclarified the values that it will contribute to society, by replacing

the existing "five social values" with "three social values" to be created by the Group’s

products and technologies.

“Up to the time I entered my current position, I was single-minded about glass production. I

didn’t think at all about what happened next. However, we’ve heard that Tokyo will run out

of reclaimed land for disposal use in 20 years, and disposal is still occurring rapidly.

What should we think about the current situation? Questions of economic rationalization

remain, but AGC is making every effort to move closer to a circular recycling society, for

the sake of our future.”

INTERVIEWEE

YOSHIHIRO NAGAO

Group Leader

Sustainable Management Initiatives Group

Architectural Glass Asia Pacific Company

NAOYA KOBAYASHI

Manager

Sustainable Management Initiatives Group

Architectural Glass Asia Pacific Company

AGC Inc.

1-5-1, Marunouchi, Chiyoda-ku, Tokyo, Japan

Established in 1907. Founder Toshiya Iwasaki took on the challenge of manufacturing Japan’s first flat glass. Achieving domestic production in 1909, the company has gone on to currently hold the top share of the global market, and in addition to building glass, produces glass for automobiles, smartphones, tablets, and electronic components. The company also has extensive experience dealing with chemical products and in the life sciences and ceramics fields. One of the world’s largest glass manufacturers, AGC has 7,753 employees (as of December 31, 2023), and is one of the components of the Nikkei Stock Average.