2024.03.21

Mitsubishi Kakoki Kaisha has developed the world’s first electric field filtration technology - Secret of the technology that enables filtration of even ions without clogging the filter

Electric Field Filter® “Ele-FilTM”

Generally, when speaking of filtration methods, the act of “filtering” through a filter medium (filter), as done with an in-home water purifier, comes to mind. With this method, filters become clogged with extended use, requiring periodical changes. To overcome this drawback of the conventional filtration method, electric field filtration, an epoch-making technology, was born. The product created with this technology is Electric Field Filter® “Ele-FilTM” of Mitsubishi Kakoki Kaisha (MKK), which uses an electric field to enable filtration of even ions without clogging the filter. Mr. Shinichi Sakemi, Head of Technology Development & Production Management Headquarters and Executive Officer, and Mr. Kazuki Omori, Technical Advisor, Research and Development Department, who were involved in the development of this technology, provided an explanation.

Focusing on the fact that particulates in water are negatively charged

The traditional separation method involving direct filtration of particulates through filter media is “contact filtration,” in which particulates contact the filter media.

Conventional filtration method:

Undiluted solution

Negatively charged particulates

Filtrate

Conventional filter [with large pores]

Before loading of undiluted solution

After loading of undiluted solution

Fine particles pass through (without electric field barrier)

“With contact filtration, if the filter medium has large pores, small particles pass through

the filter medium along with the filtrate.

Therefore, it is necessary to use a filter medium

with even smaller pores than small particles. However, when a filter medium with fine pores

is continuously used, a sedimentary layer, called a cake layer, forms. This causes the fine

pores of the filter medium to become clogged and significantly reduces the filtration rate.

In addition, this method, which involves pushing out filtrate with pressure, needs a large

driving force for filtration. These drawbacks have long presented a challenge,” Mr. Omori

explained.

A solution to this challenge is MKK’s Electric Field Filter®

“Ele-FilTM.”

Ele-FilTM was

developed focusing on the fact that most particles dispersed in solution are weakly charged

with electricity.

“Most particulates floating in water have negatively charged surfaces. Due to this property,

when electrode filter plates are placed and direct-current negative voltage is applied to

them, a negatively charged electric field barrier forms. When negatively charged

particulates approach the electric field barrier created by the negatively charged electrode

filter plates, a large repulsive force is produced between the negative charges to float up

the particulates. This is a phenomenon following Coulomb's law, and the technology utilizing

this law has enabled filtration without clogging of the filter media. Non-contact

filtration, which avoids the contact of particulates with the electrode filter plate to the

extent possible, is the mechanism of Ele-Fil. This mechanism allows the filtration rate to

be maintained with a small driving force and also increases the filtration capacity per

filter area,” explained Mr. Omori.

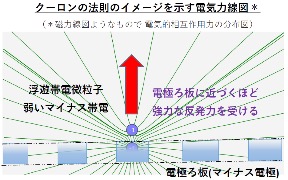

Diagram of electric field lines visualizing Coulomb's law*

(*Distribution diagram of electric interactive force, like a diagram of magnetic lines of

force)

Electrically charged floating particulates

Weakly negatively charged

As particulates get closer to the electrode filter plate, a stronger repulsive force is

applied to them

Electrode filter plate (negative electrode)

Filtration method using Ele-FilTM:

Electrode

Undiluted solution

Negatively charged particulates

Attractive interaction

Repulsive interaction

Electrode

Electric field barrier

Filtrate

Before loading of undiluted solution

After loading of undiluted solution

Electric field barrier works

Electrophoresis*3 and the electrical force of the repulsive interaction to keep

charged

particles away from the surface of the electrode filter plate are used to filter a solution.

Electrical interactive force keeps the charged particles and the electrode filter plate

separate, thereby enhancing the filtration rating.

*3 Electrophoresis: A phenomenon where charged substances in a solution

move across

the electric field

Succeeded in filtering aqueous blue dye to produce colorless and transparent water, a challenge that has previously been difficult to overcome!

Electric field filtration, or non-contact filtration, is a next-generation filtration

technology that has overcome the challenge associated with conventional contact filtration

and is compatible with a wide range of filter media, from microfiltration (MF) membranes,

with a pore size of 50 nm to 5 μm; ultrafiltration (UF) membranes, with a smaller pore size;

and nanofiltration (NF) membranes, with an even smaller pore size; to reverse osmosis (RO)

membranes.

*1 μm = 1/1000 of 1 mm; 1 nm = 1/1000000 of 1 mm

In the field of water purification, use of Ele-Fil enables separation of bacteria such as E.

coli and Shigella, viruses such as hepatitis A virus and influenza virus, and proteins. With

Ele-Fil, even aqueous blue dye ink containing 1 to 3 nm molecules, which have been difficult

to filter out by the conventional membrane filtration, can be separated into concentrated

dye and colorless and transparent filtrate. Even sodium ions and nitrate ions, with a size

of 1 nm or smaller, can also be filtered.

“In conventional contact filtration, a suitable filter medium has to be selected from among

an array of filter media according to the particle size of the substance to be separated, in

order to create the separation system. In contrast, Ele-Fil can adjust the filtration rating

with the strength of the electric field applied to the electrode filter plates and so needs

only 3 or 4 types of filter media sandwiched between the electrode filter plates to cover MF

membrane, UF membrane, NF membrane, and RO membrane,” explained Mr. Omori.

Separation of rare materials with Ele-Fil may change the industry

Ele-Fil is expected to find application in diverse fields, including algae biomass,

beverages, fermentation, brewing, life sciences such as bio-pharmaceutical discovery,

electronics/semiconductor materials, and bioplastics.

“This technology is likely to efficiently separate or extract a wide array of substances

blended in liquid, including rare metals, precious nutrients, and pigments. Furthermore, by

minimizing damage to extracts with a non-contact filtration method, the technology may

contribute to the medical field. Meanwhile, we have long been engaged in research on

microalgae including chlorella. Whereas the use of oil extracted from microalgae as SAF

(sustainable aviation fuel) and alternatives to fossil fuel has already started to be

commercialized, algae contain many kinds of rare substances, besides oil. These substances

can be used as raw materials of dyes, plastics, pharmaceuticals, cosmetics, sweeteners,

foods, seasonings, etc. Finding how to separate or extract them in an energy- and

cost-saving manner is key to the successful commercialization of products using them. We

hope that Ele-Fil will serve as the technology and product that plays a leading role in

those efforts,” said Mr. Sakemi.

MKK is involved in continued R&D efforts to increase the applications of Ele-Fil through

further enhancement of filtration efficiency, with the aim of its social implementation.

“To apply Ele-Fil to filtration, the object to be separated needs to have electrochemical

properties. The properties have not yet been sufficiently elucidated to be made full use of.

We are currently going ahead with research to enhance the performance of Ele-Fil even

further, together with Mukai Lab, Graduate School of Engineering, Nagoya University, which

works on the research theme of separation process engineering for substances in liquid based

on separation membrane and filter media technologies,” said Mr. Omori.

There are rising expectations for the creation of a new industry using Ele-Fil in the

future.

INTERVIEWEES

SHINICHI SAKEMI

Head of Technology Development & Production Management Headquarters

Executive Officer

KAZUKI OMORI

Technical Advisor, Research and Development Department

Mitsubishi Kakoki Kaisha, Ltd.

2-1 Ohkawa-cho, Kawasaki-ku, Kawasaki, Kanagawa, Japan

Established in 1935 as Kakoki Seisaku, Ltd., a company to domestically manufacture machinery for the chemical industry, financed by Mitsubishi Group companies. Engaged in construction and engineering of industrial and chemical plants and environmental control facilities and manufacturing of various single industrial machines as its mainstay business. As an engineering company with extensive manufacturing capabilities, strongly pushes forward the development of the industrial world by manufacturing and constructing the machinery and equipment required for wide-ranging fields, including city gas, petroleum, hydrogen, electricity, chemicals, pharmaceuticals, food, semiconductor, biotechnology, air pollution control, water treatment, and new energy sources.