2024.03.21

Dai Nippon Toryo has launched a business in the area of life sciences! Why did DNT launch the world’s first “extracellular vesicle immunochromatographic kit” on the market?

DNT’s business is not limited to coatings!

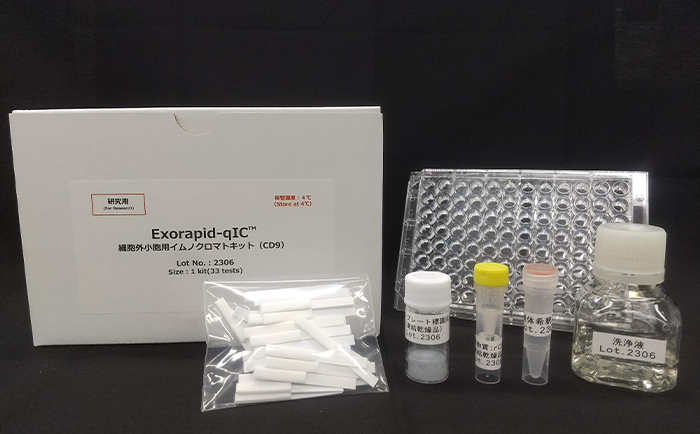

In July 2023, Dai Nippon Toryo (DNT) launched “Extracellular Vesicle Immunochromatographic

Kit Exorapid-qICTM (CD9).” This is the world’s first immunochromatographic kit

for research

use targeting “extracellular vesicles (EVs),” particles secreted from cells.

An

immunochromatographic kit refers to a test kit to determine positivity for certain targets

by appearance of a colored test line in the region on which a test sample has been applied,

as represented by diagnostic kits for influenza virus or coronavirus. Why did DNT, a company

specialized in coatings, launch a product in the area of life sciences onto the market? This

is closely linked to the company’s nanoparticle technology.

Our 20-year experience in nanoparticle technology led us to believe that “we can produce such a product ourselves”

EVs, contained in blood and urine, are becoming more and more a focus of research, since

they contain information on the original cells from which they have been secreted. For

example, progress in research on EVs secreted from cancer cells is expected to allow early

diagnosis of cancer.

“Extracellular Vesicle Immunochromatographic Kit Exorapid-qICTM (CD9),” which

contributes to

promotion of extracellular vesicle research, was born from a combination of DNT’s research

on “anisotropic noble metal nanoparticles” and Shimadzu Corporation’s research on “life

sciences.”

In general, coating utilizes a technology involving stable dispersion of particles in

liquid.

“By applying our coating technology, we have pursued research on a technology to stably

synthesize anisotropic (non-spherical shape) noble metal nanoparticles, such as disc-shaped

gold nanoparticles (gold nanoplate) and silver nanoparticles (silver nanoplate), for

approximately 20 years,” said Mr. Yoshikazu So and team leader Mr. Yuta Miyazawa, Functional

Materials Development Group, Speciality Business Dept., DNT.

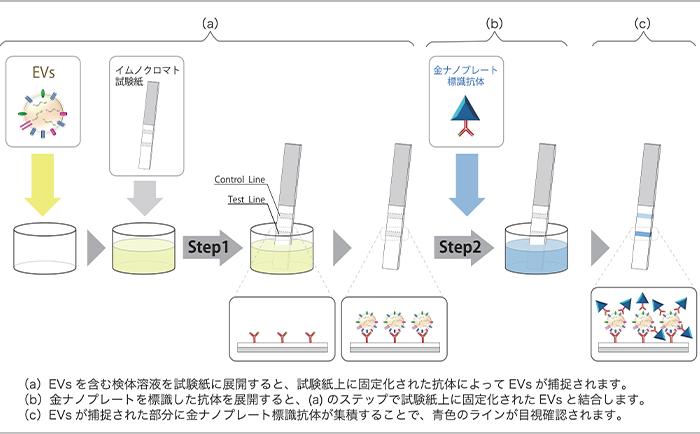

EVs

Immunochromatography test strip

Gold nanoplate-labeled antibodies

(a) When a sample solution containing EVs is applied on a test strip, EVs are captured by

antibodies immobilized on the test strip.

(b) When gold nanoplate-labeled antibodies are applied, they bind to the EVs immobilized on

the test strip in Step (a).

(c) When gold nanoplate-labeled antibodies accumulate in the part where EVs have been

captured, a blue line is visually observed.

“We developed anisotropic particles originally as a coating material that cuts off infrared

light emitted from displays. Then, in a search for other applications of this anisotropic

particle technology, we found its potential in the life sciences market. In

immunochromatography, metal nanoparticles have been widely used to have a test line develop

a color. However, we noted that this method was disadvantageous in that due to few color

variations, test results are difficult to see when several viruses are simultaneously

tested. Then, with the belief that we, as a coating company, can help develop a multicolor

test kit, we changed direction and strived to enter the life sciences area,” explained Mr.

Miyazawa.

From 2015, DNT ran a booth at exhibitions to introduce the technology to diagnostic agent

manufacturers. Each time, however, the response of such manufacturers was that they

preferred utilizing mature, commercialized technology.

“When it comes to testing, reliability is important, and so, most of such manufacturers

place an emphasis on adoption results of products or technologies.

Hence, we were unable to find the first company that would adopt our technology. Then, we

began to think that it

might be earlier to create a test kit ourselves in around 2017. Just around that time, our

brother company Shimadzu Corporation became interested in our technology, and a joint

development project with them started,” Mr. Miyazawa explained.

Mr. Miyazawa was temporarily transferred to Shimadzu Corporation and worked at the Shimadzu

Corporation research facility. There he himself was involved in the research on cancer

diagnosis using EVs secreted from cancer cells.

“EV detection experiments are expensive and time-consuming. Some experiments need a device

costing over 10 million yen or take as long as 3 to 5 hours to complete. We wondered what we

should do to make research more rapid and conceived that if immunochromatography enables

low-cost, rapid testing, there would be a high demand for the technology-based product. This

expectation increased our motivation to develop such a product,” said Mr. Miyazawa.

Entered an unformed market with a prototyping strategy

The market of EV-based research reagents is growing at an annual rate of more than 30%.

Given that DNT’s kit is the first-to-market, proposal-based product, there still remain

uncertainties, although high demand is expected. Nevertheless, they chose to face the

challenge of “putting it on the market even a day earlier.”

“We judged this product to be the most amenable to a prototyping strategy, in which a

product is trial-marketed and then real customer feedback is incorporated in the improvement

and development processes. While we were aiming at early launch of the product, we had to

ensure satisfactory quality, needless to say. In a struggle to overcome this challenge, we

conducted a lot of experiments, with several experiments run in parallel, allowing for any

unexpected results from the experiments. Moreover, as we, a coating company, do not possess

the full set of manufacturing equipment, we asked for help from other companies. Setting up

the system for that is also our first experience,” said Mr. Miyazawa.

In the process of this development project, a patented technology of TOPPAN Inc. also became

necessary. Thus, we proceeded with the research and development, blessed with cooperation

and kindness of many people. The completed “Extracellular Vesicle Immunochromatographic Kit

Exorapid-qICTM (CD9)” does not need dedicated devices, unlike conventional EV

detection

experiments, and this has reduced the initial cost. Furthermore, the kit has reduced the

testing time to approximately 45 minutes and is also easy to handle, making it ideal for EV

research start-up or simple evaluation.

In fiscal year 2023, DNT is widely promoting the product by disseminating information

through presentations at academic meetings and webinars, with an eye toward achieving a

large market share.

They ran a booth at the annual meeting of the Japanese Society for

Extracellular Vesicles, held in October 2023, to disseminate information to researchers.

They will continue with efforts to refine the extracellular vesicle immunochromatographic

kit and at the same time to pursue the development of new technology using noble metal

nanoparticles.

“Noble metal nanoparticles absorb a certain wavelength depending on the shape and thus allow

large color variations. We are receiving inquiries from a lot of customers who would like to

use the technology. We are also pouring efforts in sales of metal oxide nanoparticles, which

are applied to anti-reflection film and the like. We showcased the metal oxide nanoparticles

in ‘FILMTECH JAPAN,’ held in October 2023, and are receiving more and more inquiries about

them as a coating material,” said Mr. Miyazawa.

Making things is challenging and laborious. However, Mr. Miyazawa and Mr. So say, “whether

taking the first step or not determines our future, and success of our efforts requires the

support and cooperation of the people involved. We hope we can work for a successful future

together with people from various fields, not limited to those belonging to Mitsubishi

Group, with a never-give-up spirit.”

With its catchphrase “DNT’s business is not limited to coatings!” in mind, DNT will dedicate

its efforts to opening up new business in wide-ranging fields.

INTERVIEWEE

YUTA MIYAZAWA

Team Leader, Functional Materials Development Group, Speciality Business Dept.

YOSHIKAZU SO

Functional Materials Development Group, Speciality Business Dept.

Dai Nippon Toryo Co., Ltd.

SR Bldg. NAGAHORI, 1-18-11 Minamisemba, Chuo-ku, Osaka, Japan

Established in 1929. A comprehensive coating manufacturer with the mainstay business of structure anticorrosive coatings/heavy-duty anticorrosive coatings and building material coatings. Boasts the top market share in structure anticorrosive coating products. Conducts research in the fields of “analysis and physical properties,” “paint and anti-corrosion theories,” “functional polymer material design,” and “coat film formation and coating technologies.” In addition, is actively engaged in new business areas including antistatic coating materials, refractive index adjusting coating materials, and heat-ray absorbing coating materials.